How Technology is Revolutionizing Logistics in the Netherlands

Technology is transforming the logistics industry in the Netherlands at an unprecedented pace, reshaping how goods are stored, managed, and transported across Europe and beyond. The country’s strategic location as a major European logistics hub has made it a fertile ground for adopting cutting-edge innovations that boost efficiency, transparency, and sustainability in supply chain operations. From smart warehouses to autonomous vehicles, technology is driving the next generation of logistics services.

One of the most significant technological advances is the widespread implementation of warehouse automation and robotics. In the Netherlands, many logistics companies have invested in automated storage and retrieval systems (AS/RS), robotic picking arms, and conveyor systems that streamline warehouse operations. These technologies reduce human error, speed up order processing, and enable 24/7 operations with consistent accuracy. Automation also helps warehouses maximize space utilization by efficiently managing high-density storage configurations, which is critical in the country’s often limited warehouse real estate.

Digital platforms and advanced warehouse management systems (WMS) have revolutionized inventory control and fulfillment processes. These systems provide real-time visibility into stock levels, order statuses, and shipment tracking, allowing logistics providers and their customers to make informed decisions quickly. Integration with enterprise resource planning (ERP) software and e-commerce platforms enables seamless data exchange and improved coordination across the supply chain. In the Netherlands, where cross-border trade is a daily activity, this connectivity helps businesses comply with customs regulations and manage complex logistics networks efficiently.

The rise of Internet of Things (IoT) technology is another game-changer. Sensors attached to shipments, pallets, and vehicles provide continuous data on location, temperature, humidity, and other environmental factors. This real-time monitoring enhances supply chain transparency, especially for sensitive goods such as pharmaceuticals, food, and electronics. IoT enables predictive maintenance of vehicles and equipment, reducing downtime and preventing costly disruptions. Dutch logistics providers increasingly use IoT to offer value-added services that meet stringent quality and compliance standards.

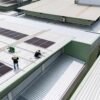

Sustainability is a growing focus in the Netherlands, and technology is key to advancing greener logistics practices. Electric trucks, drones, and route optimization software reduce carbon emissions and fuel consumption. Innovative last-mile delivery solutions, such as electric cargo bikes and autonomous delivery robots, are becoming common in Dutch cities, helping to ease traffic congestion and lower environmental impact. Advanced data analytics also empower companies to optimize warehouse operations and transportation schedules to minimize waste and energy use.

Artificial intelligence (AI) and machine learning are enabling smarter decision-making in logistics. AI algorithms analyze vast amounts of data to forecast demand, optimize inventory levels, and predict potential supply chain disruptions. These insights help logistics companies in the Netherlands to improve service reliability and reduce operational costs. Moreover, AI-driven chatbots and customer service tools enhance communication and responsiveness in client interactions.

In summary, technology is revolutionizing logistics in the Netherlands by driving automation, connectivity, sustainability, and intelligence across the supply chain. Companies that embrace these innovations—leveraging smart warehouses, IoT, AI, and green technologies—are better positioned to thrive in a highly competitive, fast-evolving market. As the logistics landscape continues to advance, the Netherlands remains at the forefront of adopting tech-driven solutions that set new standards for efficiency, reliability, and environmental responsibility.